LeanLineTM is HOLO/OR’s innovative solution for transformation of a round input beam into a narrow laser line, useful in various high power applications, especially with UV and green wavelengths (343, 355, and 532 nm). These applications include laser lift off, flexible display production, solar cell processing and polymer welding.

HOLO/OR offers a robust 2-module system that converts a low coherence, round input into a narrow line with a user determined length (100mm-750mm).

Our solution is based on proprietary diffractive beam shaping concepts and can be tailored to any wavelength from 193nm deep UV to 1600 nm IR lasers. By utilizing our solution, you can use lower power, lower cost lasers to achieve the same power density in a thin line, allowing major savings.

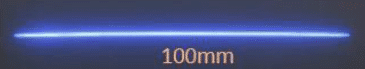

Laser 532nm, line 64mm x 28um

Laser 355nm, line 100mm x 11um

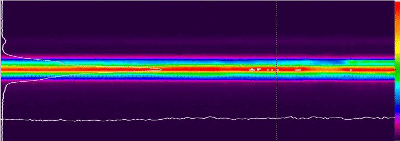

Profile along laser line

Diffractive solution advantages:

- Easy alignment and installation

- Extremely high precision for beam quality transformation, achieved by the lithography production process

- A fully transmissive (no reflection), on-axis system

- Aberration free

- Can be easily modified to produce different line lengths and widths

- No internal focus points

- Available in a wide spectral range from DUV to NIR.

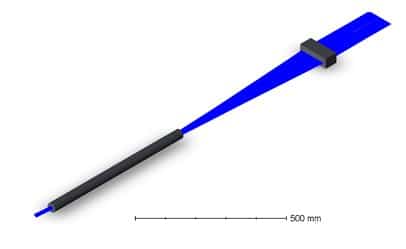

The solution includes two modules:

- The first module is M^2 transformation module. It is used for beam quality transformation and thin line beam shaping.

- The second module is used for line length control and focusing in the narrow axis.

Applications:

Laser annealing to improve process quality in a variety of industries:

- Lift off process for manufacturing flexible displays

- OLED displays

- Semiconductor devices

- Thin-film solar cell production

- Sensor production

Materials:

Processing of a broad range of materials including:

- Silicon

- Silicon on glass

- Polymers

- ITO on glass

Specifications:

1. One wavelength per system, max spectral width 2% of input wavelength

2. Can be changed to other line widths up to 750mm. contact us for details.

3. Dependent on wavelength, working distance & M2. This value is for 355nm, working distance 125mm and M2=25.

4. Can be changed according to customer requirements

Comparison between LeanLine solution and traditional optics:

The LeanLine system achieves power density and depth of focus which are impossible to achieve using standard focusing optics with a multi-mode laser.

The above parameters show that generating a long line (hundreds of millimeters) with traditional optics, it is needed to use several large and expensive cylindrical lenses. Even when a smaller line is desired, there is an innate tradeoff between depth of focus and achievable thickness.

With the LeanLine concept, the M2 transformation enables long DOF while maintaining a narrow line thickness. For shorter lines, it also enables the use of single cylindrical lenses that are commercially available. The following are real images taken after LeanLine M2 transformation module prototypes.

Vertical beam quality factor after conversion is ~ 2.

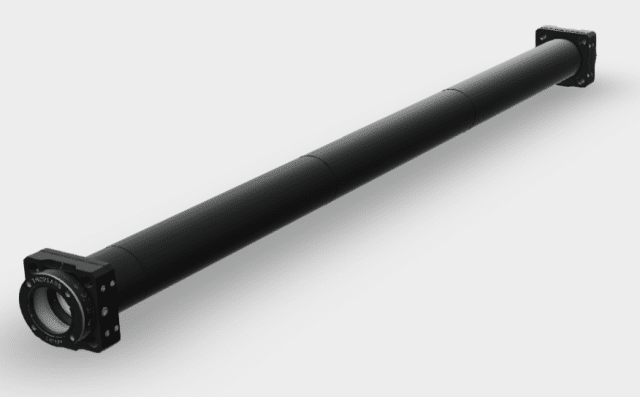

M2 TRANSFORMATION MODULE:

Holo/Or’s M^2 transformation module is a cost effective solution to get low M^2 and almost single-mode (SM) properties in one axis using a multi-mode (MM) source laser, for customers who prefer to use their own focusing setup, and not the the intire Leanline system.

The M^2 parameter (beam quality factor) represents the beam propagation of a collimated Gaussian laser beam. The output shape consists of focused sections separated by equal distances with near SM quality in one axis (fast axis) and highly MM in the second axis (slow axis). These separated low M^2 sections can be reshaped and focused to a thin diffraction limited line, with good homogeneity, suitable for the needs of material processing applications.

The solution can be tailored to any wavelength based on the user needs from DUV 193nm to 1940nm NIR lasers.

This M^2 transformation module is a solution suitable for customers who use multi-mode lasers for laser line systems, in the fields of electronic devices and components, solar, automotive, energy storage, research and more.

Unlike other transformation approaches, Holo/Or’s diffractive M^2 transformation module is extremely easy to align, maintains the same optical axis and has no high NA optics. These advantages make it easy to integrate with existing line focusing optics. This module comes pre-aligned and sealed- just insert into your beam path and after a minute of fine adjustment you will have an M^2 transformed beam.

Contact us for more information or for a custom solution.

Real images taken after M^2 transformation module prototypes:

355 nm system

532 nm system

advantages:

- Near single-mode properties for low cost

- Easy alignment and installation

- Extremely high precision for beam quality transformation, achieved by the lithography production process

- A fully transmissive (no reflection), on-axis system

- Aberration free

- No internal focus points

- Available in a wide spectral range from DUV to NIR

- High quality UV fused-silica based elements

Applications:

- Material processing

- Laser annealing

- Laser crystallization

- Laser machining

- Laser Welding

- Lift off process

- Thin-film solar cell production

Specifications:

One wavelength per system, max spectral width 2% of input wavelength.

LeanLine M2 transformation module video